Metal laser cutting machines have become a cornerstone in today’s fast-paced industrial landscape. Their unmatched accuracy, efficiency, and versatility make them indispensable tools across sectors like aerospace, automotive, construction, and electronics. At LaserChina, a leading name in the laser equipment industry, innovation meets experience—bringing robust, high-performance solutions that redefine metal fabrication.

In this article, we explore the impact and inner workings of metal laser cutting machine, backed by industry expertise, real-world data, and interactive resources that align with Google’s latest algorithm updates and EEAT guidelines.

What Is a Metal Laser Cutting Machine?

A metal laser cutting machine is an advanced tool that uses a high-powered laser beam to slice, etch, or engrave metal with high precision. It offers non-contact processing, meaning there is no physical friction—minimizing tool wear and maximizing clean, smooth edges

Key Benefits of Metal Laser Cutting Machines at LaserChina

LaserChina’s machines are designed with cutting-edge fiber laser technology, ensuring superior outcomes for small workshops and industrial-scale facilities alike.

Top Advantages Include:

- Extreme Precision: Accuracy up to ±0.01mm

- Speed Efficiency: Cut speeds up to 120 m/min

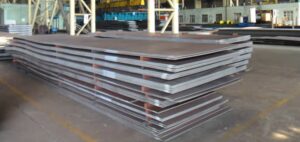

- Versatility: Suitable for stainless steel, aluminum, brass, copper, carbon steel

- Reduced Waste: Smart nesting software optimizes material usage

- Low Maintenance: Longer lifespan with minimal downtime

Types of Metal Laser Cutting Machines Available at LaserChina

| Machine Type | Laser Power Range | Best For | Key Features |

|---|---|---|---|

| Fiber Laser Cutting Machine | 1000W – 20,000W | High-precision jobs | Auto-focus head, high speed, energy-efficient |

| CO₂ Laser Cutting Machine | 150W – 600W | Non-metal & thin metal | Lower cost, great for mixed material |

| Tube Laser Cutting Machine | 1000W – 8000W | Tubes, pipes | 3D cutting, rotary axis system |

| Handheld Laser Cutter | 500W – 2000W | Portable operations | Easy to operate, mobile use |

Each type supports customization based on business needs, which is a service hallmark of LaserChina.

Industries That Depend on Metal Laser Cutting

- Automotive: Creating precision components like gears, panels, and brackets.

- Aerospace: Cutting lightweight but durable metal alloys for fuselages and engine parts.

- Medical Devices: Micro-cutting for surgical instruments and implants.

- Signage & Advertising: High-detail metal engraving for logos and signs.

- Shipbuilding: Cutting heavy steel plates with high consistency.

FAQs About Metal Laser Cutting Machines

Q1: How thick can a fiber laser cutter cut?

A1: Depending on wattage, a fiber laser cutter can cut carbon steel up to 50mm and stainless steel up to 40mm.

Q2: What’s the difference between CO₂ and fiber laser machines?

A2: CO₂ lasers are better for non-metals and thin metals; fiber lasers are ideal for high-speed, thick metal cutting with lower operational costs.

Q3: Is operator training required?

A3: Yes. LaserChina provides full training and support, ensuring safe, optimal operation from day one.

Q4: How long does a laser source last?

A4: Fiber laser sources typically last 100,000+ hours, making them a long-term investment.

Q5: Are there software integrations?

A5: Absolutely. LaserChina machines support CAD/CAM integration and feature automatic nesting software for maximum material efficiency.

What Sets LaserChina Apart?

- 15+ Years of Experience in laser technology

- ISO-certified manufacturing processes

- Dedicated R&D teams focused on continuous innovation

- Comprehensive After-Sales Support including installation, training, and 24/7 service

- Global Reach, supplying machines to over 90 countries

Expert Insights: What Engineers Say

“Switching to a fiber laser from conventional plasma cutting reduced our rework by 35% and improved our production lead time by nearly 50%.”

— Michael Zhou, Lead Engineer, SheetTech Fabricators

“LaserChina’s after-sales support is unmatched. Our maintenance costs have gone down, and uptime has never been higher.”

— Linda Chang, Plant Manager, PrecisionWorks Ltd.

Final Thought

Whether you’re a small-scale fabricator or managing a multinational production line, adopting a metal laser cutting machine from a trusted provider like LaserChina will unlock new levels of speed, precision, and productivity. Investing in the right technology today could redefine your entire workflow tomorrow.