In the world of electronics and precision devices, thermal expansion mismatch between materials is one of the most common causes of component failure. This issue is especially critical in diode manufacturing, where temperature-sensitive applications demand long-lasting, highly stable components. That’s where the Kovar Sheet becomes indispensable.

Kovar, a low-expansion nickel–cobalt ferrous alloy, has become the material of choice for various high-reliability applications, especially in diode manufacturing. Its unique properties make it ideal for hermetic sealing with glass or ceramic, which is crucial in protecting sensitive diode elements from environmental degradation.

In this blog, we explore the properties of Kovar Sheet, its advantages, and its critical role in ensuring high-stability diode performance.

What is Kovar?

Kovar is an iron-nickel-cobalt alloy (typically 29% nickel and 17% cobalt) with a coefficient of thermal expansion very similar to borosilicate glass. This property makes it ideal for glass-to-metal and ceramic-to-metal seals. It is commonly available in various forms like rods, bars, plates, and Kovar Sheet.

The development of Kovar in the early 20th century revolutionized the electronics industry, offering a solution for joining dissimilar materials without the risk of cracking or seal failure due to temperature fluctuations.

Key Properties of Kovar Sheet

Kovar Sheet offers a range of attributes that make it well-suited for diode manufacturing:

- Controlled thermal expansion: Matches the expansion rates of ceramics and glass used in diode housings.

- Excellent dimensional stability: Ensures consistent performance under thermal cycling.

- Superior hermetic sealing capabilities: Critical for diode reliability.

- High strength and machinability: Suitable for precision forming and shaping.

- Good corrosion resistance: Ensures long-term operation in harsh environments.

These characteristics make Kovar Sheet a critical enabler of both commercial and military-grade diode applications.

Why Kovar Sheet is Critical for Diode Manufacturing

1. Thermal Expansion Compatibility

Diodes are often encapsulated in glass or ceramic housings to provide insulation and protection from the environment. However, traditional metal materials expand and contract at different rates compared to glass or ceramic. This differential movement can result in fractures or leaks, especially under thermal stress.

Kovar’s closely matched expansion coefficient minimizes this risk. When used in diode packages, Kovar Sheet maintains structural integrity even during extreme temperature changes, preserving the hermetic seal around the diode.

2. Hermetic Sealing for Longevity

High-stability diodes, especially those used in aerospace, military, and medical electronics, require airtight seals to prevent moisture ingress, which can degrade semiconductor performance or cause catastrophic failure.

Kovar Sheet is often bonded to glass or ceramic materials using controlled heat-sealing processes. The alloy’s compatibility with glass-forming techniques ensures a tight, vacuum-grade seal, which is essential for protecting the sensitive p-n junctions inside the diode.

3. Resistance to Harsh Environments

Diodes in industrial and aerospace applications are exposed to a variety of hostile conditions such as high radiation, chemical exposure, and fluctuating temperatures. Kovar Sheet’s resistance to oxidation and corrosion extends the service life of these diodes, even in extreme conditions.

4. Dimensional Precision and Fabrication

In diode manufacturing, even a slight deviation in dimensions can compromise the effectiveness of the final product. Kovar Sheet can be precision cut, stamped, or laser-machined to tight tolerances, making it ideal for small-scale, high-precision diode packages.

This ability allows diode manufacturers to create intricate housings and connectors that align perfectly with other components, ensuring optimal electrical performance and mechanical fit.

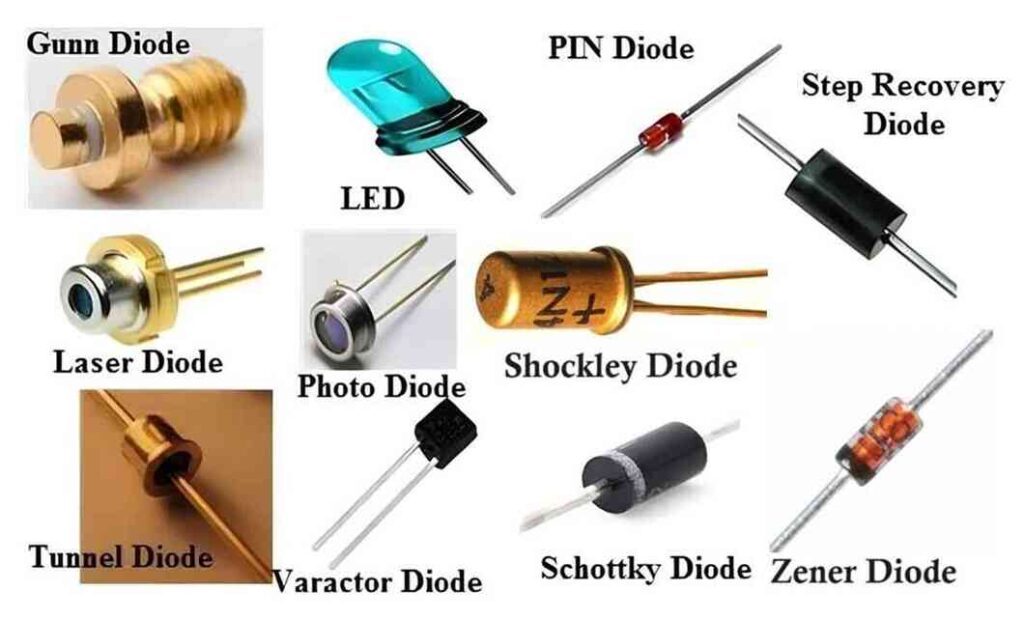

Common Diode Applications Utilizing Kovar Sheet

- Microwave Diodes: These are used in radar systems, satellite communication, and microwave ovens. Kovar’s stability ensures minimal signal degradation over time.

- Power Diodes: Found in power conversion and rectification systems, Kovar helps maintain their integrity under high-voltage and high-current loads.

- Zener Diodes: Used for voltage regulation, Kovar Sheet ensures a consistent sealing structure, essential for protecting against voltage surges.

- Photodiodes: In cameras and optical sensors, maintaining sensitivity is crucial. Kovar housing shields photodiodes from external light leaks and moisture.

- Schottky Diodes: Common in high-speed switching applications, these diodes benefit from Kovar’s ability to minimize package stress during rapid on/off cycles.

Advantages Over Other Alloys

While alternatives like stainless steel or aluminum are used in some electronic packages, they do not offer the same level of expansion matching or hermetic seal compatibility as Kovar Sheet. For instance:

- Aluminum: While lightweight, it expands more than glass, increasing the risk of seal breakage.

- Stainless Steel: Offers corrosion resistance but lacks thermal compatibility with glass, limiting its use in high-stability diodes.

In contrast, Kovar Sheet offers the ideal balance of thermal compatibility, strength, and machinability, making it the industry standard for diode applications where performance cannot be compromised.

The Role of a Reliable Kovar Sheet Supplier

Choosing a trusted supplier for Kovar Sheet is essential. High-quality Kovar must meet ASTM F15 standards for composition and performance. A reliable supplier ensures:

- Material traceability and certifications

- Consistent sheet thickness and flatness

- Custom cutting and finishing services

- On-time delivery for large and small volume orders

Working with a certified supplier guarantees that your Kovar Sheet meets the exact specifications required for your diode manufacturing process.

Conclusion

As the demand for high-performance electronics continues to rise, especially in aerospace, telecommunications, and medical devices, the importance of reliable and stable components becomes even more critical. Kovar Sheet offers unmatched thermal expansion compatibility, sealing performance, and mechanical stability, making it an indispensable material in high-stability diode manufacturing.

Whether you’re producing small-signal diodes or high-voltage rectifiers, integrating Kovar into your design ensures longer life, better performance, and greater resistance to environmental stress. For manufacturers seeking long-term reliability and consistency in diode performance, Kovar Sheet remains the gold standard.