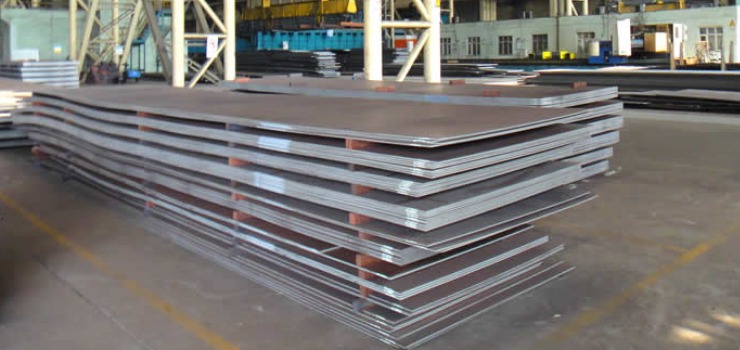

When it comes to modern heavy engineering, the demand for materials that can withstand extreme stress, pressure, and harsh environments is higher than ever. One such material that stands out in this demanding landscape is the S960QL Steel Plate. Known for its exceptional strength, durability, and toughness, this steel grade has revolutionized structural and engineering projects across various industries.

In this blog, we’ll explore in detail how S960QL Steel Plate enhances heavy engineering projects. From its unique properties and benefits to its real-world applications, we’ll break it down in a simple and understandable manner.

What is S960QL Steel Plate?

S960QL Steel Plate is a high-strength quenched and tempered structural steel grade. The “S” in S960QL stands for “structural”, “960” denotes the minimum yield strength in megapascals (MPa), and “QL” indicates that the steel has been quenched and tempered for improved toughness at low temperatures.

This steel plate is designed to provide both high strength and excellent weldability, making it a popular choice for demanding structural applications.

Key Properties of S960QL Steel Plate

Before diving into its applications, let’s understand what makes S960QL so special. Here are the main features:

- High yield strength of 960 MPa

- Excellent toughness and impact resistance, even in cold climates

- Good weldability and formability

- Low carbon content with fine-grained microstructure

- Resistant to fatigue and wear

These properties make S960QL Steel Plate highly suited for use in extreme conditions where safety, performance, and durability cannot be compromised.

Why S960QL Steel Plate is Ideal for Heavy Engineering

Heavy engineering involves massive machinery, pressure vessels, cranes, bridges, offshore platforms, and large-scale infrastructure. These structures demand materials that offer both strength and reliability.

Here’s how S960QL Steel Plate enhances heavy engineering:

1. Superior Strength for Load-Bearing Structures

In heavy engineering, components are often under constant and extreme loads. The 960 MPa yield strength of S960QL Steel Plate means it can carry more load without deforming. This allows engineers to design lighter yet stronger structures.

Lighter structures are beneficial as they:

- Reduce transportation and installation costs

- Improve overall structural efficiency

- Require less support infrastructure

2. Improved Safety and Structural Integrity

Safety is non-negotiable in heavy engineering. Whether it’s a crane lifting tonnes of material or a bridge spanning miles, failure is not an option.

Thanks to its high impact resistance and fracture toughness, S960QL can withstand shock loads and resist brittle failure – especially in cold or harsh environments.

3. Excellent Weldability

One of the concerns with high-strength steels is weldability. But S960QL Steel Plate is engineered to allow easy and consistent welding, without compromising the structural strength.

This makes it easier for fabricators and engineers to work with the material, ensuring:

- Shorter project timelines

- Reduced labor and fabrication costs

- Fewer defects during construction

4. Resistance to Fatigue and Wear

Heavy engineering equipment often undergoes repetitive stress and movement. Fatigue and wear resistance are crucial here.

Thanks to its fine microstructure and heat treatment, S960QL Steel Plate performs exceptionally in:

- Long-term use without cracking or deformation

- Cyclic loading conditions such as in cranes or excavators

- Abrasive environments where resistance to surface wear is critical

5. Versatility in Design and Fabrication

With good formability and machinability, engineers can easily shape and customize S960QL plates for a variety of components — from flat panels to curved structures. This gives designers greater flexibility without sacrificing performance.

Applications of S960QL Steel Plate in Heavy Engineering

Let’s take a look at where exactly S960QL Steel Plates are used in the real world. These plates find their way into several critical sectors:

1. Construction Equipment

Modern construction machines such as bulldozers, excavators, cranes, and loaders benefit from lighter and stronger components made from S960QL. It improves mobility and efficiency while maintaining durability.

2. Bridges and Infrastructure

In long-span bridges or overpasses, using S960QL Steel Plate helps reduce dead weight and allows for slimmer yet robust bridge structures.

3. Cranes and Lifting Equipment

Tower cranes and mobile cranes use S960QL plates for their booms and arms, where high strength-to-weight ratio is critical for lifting heavy loads safely.

4. Offshore Structures

The marine and oil & gas industries require materials that can withstand saltwater corrosion, pressure, and cold environments. S960QL is used in:

- Offshore platforms

- Wind turbine towers

- Subsea components

5. Pressure Vessels and Industrial Tanks

For chemical plants and energy sectors, S960QL plates are used in pressure vessels where tensile strength and safety under pressure are crucial.

6. Defense and Military Equipment

S960QL is also used in armor and military-grade equipment, where strength, durability, and low weight are a priority.

Benefits of Using S960QL Steel Plate Over Conventional Steel

Here’s a quick comparison of why S960QL stands out:

| Property | Conventional Steel | S960QL Steel Plate |

|---|---|---|

| Yield Strength | 250–500 MPa | 960 MPa |

| Weldability | Moderate | Excellent |

| Weight Efficiency | Heavier | Lighter for same strength |

| Fatigue Resistance | Limited | High |

| Toughness in Cold | Low | Excellent |

| Longevity | Moderate | High |

Using S960QL not only boosts performance but can also lead to significant cost savings in the long run by reducing material usage, labor, and maintenance.

Factors to Consider When Using S960QL Steel Plate

While S960QL Steel Plate offers many advantages, it’s important to consider a few factors for optimal performance:

1. Proper Welding Techniques

Though weldable, it’s essential to use preheating and post-weld heat treatments based on the plate thickness and application.

2. Qualified Fabricators

Ensure that experienced engineers or fabricators handle the cutting, bending, and welding to maintain structural integrity.

3. Material Certification

Always source plates from trusted manufacturers who offer certification as per EN 10025-6 standards, which includes chemical and mechanical property compliance

Why Choosing the Right S960QL Steel Plate Manufacturer Matters

Not all steel plates are created equal. To get the full benefits of S960QL Steel Plate, partnering with a reliable manufacturer is key.

Look for manufacturers who:

- Use high-quality raw materials

- Follow strict quality control procedures

- Provide material test certificates

- Offer custom sizes and thicknesses

- Ensure timely delivery and global shipping

Working with a trusted supplier ensures you get consistency, performance, and peace of mind.

Final Thoughts

S960QL Steel Plate is more than just a high-strength material – it’s an engineering solution. With its unmatched strength, weldability, and resilience, it has proven to be a game-changer for heavy engineering projects.

Whether you’re designing a bridge, building a crane, or constructing an offshore platform, using S960QL can enhance performance, safety, and cost-efficiency.

If you’re in the market for reliable, high-quality steel for demanding applications, consider integrating S960QL Steel Plate into your next project. The results speak for themselves.