In the world of automotive and mechanical engineering, the performance of suspension systems directly influences safety, comfort, and durability. Central to the structural integrity of these systems are the materials used in their construction. Among them, 1045 Carbon Steel Round Bar has become a preferred choice due to its excellent mechanical properties, cost-effectiveness, and versatility. In this blog, we explore the top benefits of using 1045 carbon steel round bar in suspension design and why engineers rely on it for critical load-bearing components.

What Is 1045 Carbon Steel Round Bar?

1045 carbon steel is a medium carbon steel grade with a carbon content of approximately 0.45%. This gives it a balance of strength, hardness, and ductility—qualities that make it ideal for machining, welding, and heat treatment. A 1045 carbon steel round bar is a cylindrical solid rod of this steel, commonly used in applications requiring high wear resistance and mechanical strength.

Key properties of 1045 carbon steel include:

- Tensile Strength: 570 – 700 MPa

- Hardness (Brinell): ~170 – 210 HB

- Good machinability

- Excellent toughness and fatigue resistance

Why Suspension Systems Matter

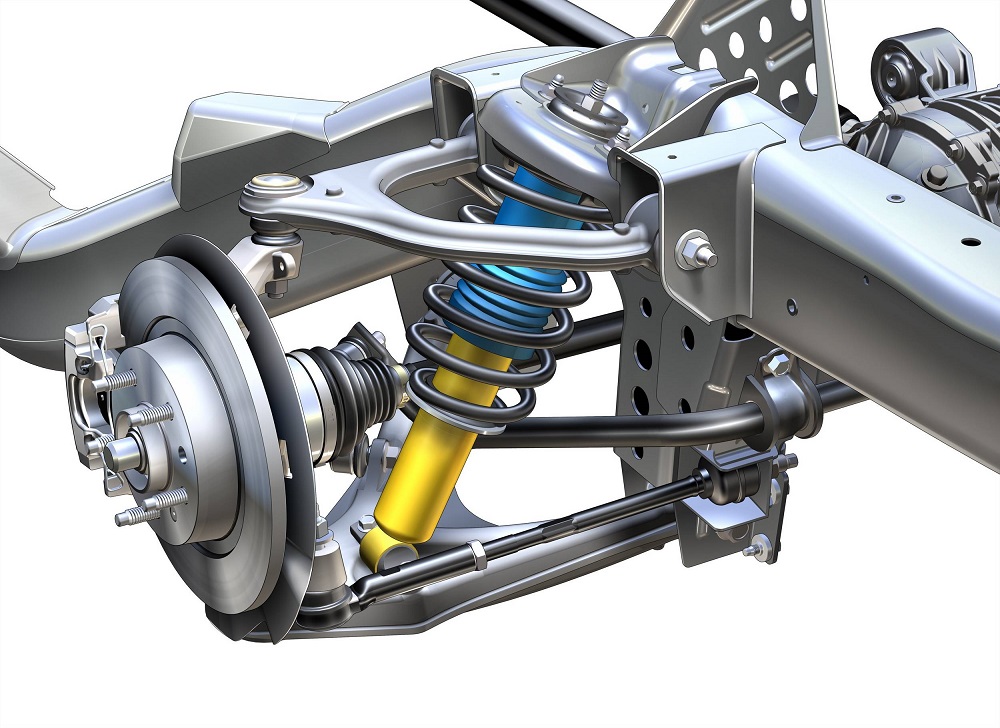

Suspension systems in vehicles serve multiple purposes:

- Absorb shocks from uneven terrain

- Maintain wheel contact with the road

- Enhance ride comfort

- Improve handling and braking

To perform these functions, suspension components like control arms, spring seats, shafts, and stabilizer links must be constructed from strong and durable materials. The 1045 carbon steel round bar fulfills these needs in several crucial ways.

1. High Strength and Load-Bearing Capacity

One of the biggest advantages of 1045 carbon steel round bar is its superior tensile strength, which makes it ideal for parts that bear high static and dynamic loads. In suspension systems, components often endure substantial stress and fatigue due to constant movement, weight shifts, and vibrations. 1045 carbon steel provides the mechanical robustness needed to ensure long-term reliability and performance under these demanding conditions.

2. Excellent Wear Resistance

Suspension systems are frequently subjected to frictional forces, especially at joints and pivot points. 1045 carbon steel, when properly heat-treated, offers excellent wear resistance, helping to reduce degradation over time. This property is vital for components such as pins, shafts, and bushings that experience frequent rotational or linear movement.

3. Enhanced Fatigue Strength

Another critical factor in suspension system performance is fatigue resistance. Over time, repeated stress cycles can lead to microcracks and eventual component failure. The 1045 carbon steel round bar, due to its carbon content and metallurgical properties, demonstrates high fatigue strength, which means it can endure millions of cycles without compromising structural integrity.

This makes it a dependable material for manufacturing torsion bars and anti-roll bars—components that are regularly subjected to bending and twisting loads.

4. Heat Treatability for Custom Performance

1045 carbon steel can be subjected to various heat treatments such as hardening and tempering to modify its properties as per design requirements. Through quenching and tempering, the hardness and toughness of 1045 steel can be enhanced, making it suitable for different suspension components with varying demands.

For example:

- Hardened round bars for high-strength bolts and fasteners

- Tempered bars for shock-absorbing bushings

- Induction-hardened bars for pivot shafts and control arms

5. Good Machinability for Complex Designs

Another key benefit of the 1045 carbon steel round bar is its excellent machinability. It can be easily turned, drilled, milled, and threaded using standard machine tools. This allows manufacturers to produce intricate suspension parts with precise dimensions and surface finishes.

Whether it’s a threaded shock absorber mount or a smooth guide rod, 1045 carbon steel can be machined into virtually any shape required for suspension system performance.

6. Cost-Effective Material Option

While high-performance alloys like Inconel or stainless steels may offer exceptional properties, they come at a higher cost. 1045 carbon steel round bar strikes a balance between performance and affordability. It provides the necessary strength and durability for suspension systems at a fraction of the cost of exotic alloys, making it an economically viable choice for large-scale production.

This is particularly important for automotive OEMs and aftermarket manufacturers looking to reduce production costs without compromising quality.

7. Weldability for Complex Assemblies

Suspension assemblies often require joining of multiple components. 1045 carbon steel, though moderately difficult to weld due to its medium carbon content, can be successfully welded with appropriate techniques and preheating. This makes it possible to create complex suspension modules that are both robust and secure.

8. Availability and Supply Chain Flexibility

Another practical benefit is the wide availability of 1045 carbon steel round bar in standard sizes and lengths. Most steel suppliers and stockists offer this material due to its popularity, which helps reduce lead times and ensures consistent supply. This reliability is crucial for high-volume suspension system manufacturing.

Common Suspension Components Made from 1045 Carbon Steel Round Bar

Here are some typical suspension parts where 1045 round bar is used:

- Control arm pins

- Shock absorber rods

- Stabilizer bar links

- Torsion bars

- Spring perches

- Axle shafts

These components must resist deformation, fatigue, and wear—and 1045 carbon steel delivers exactly that.

Conclusion

When it comes to suspension design, selecting the right material is just as important as the engineering behind the component itself. 1045 Carbon Steel Round Bar has proven to be a reliable, durable, and cost-effective material that meets the stringent demands of automotive and industrial suspension systems.

From its impressive mechanical strength to its fatigue resistance, heat treatability, and machinability, 1045 carbon steel continues to be a preferred choice for engineers and manufacturers worldwide. As the transportation and mobility sectors push for stronger, safer, and more efficient systems, the role of high-performance materials like 1045 carbon steel round bar will remain indispensable.